Introduction

In today's digital age, electronic devices play a crucial role in our daily lives. From smartphones and laptops to industrial machinery and medical equipment, electronic devices are ubiquitous and essential for communication, work, and entertainment. However, as the number of electronic devices continues to increase, so does the risk of electromagnetic interference (EMI) disrupting their operation. EMI can cause malfunctions, data corruption, and even equipment failure, highlighting the importance of effective shielding solutions such as shielded cable. In this article, we will explore the significance of shielded cable in mitigating EMI, its construction, types, applications, and benefits.

Understanding Electromagnetic Interference (EMI)

Electromagnetic interference (EMI) refers to the disturbance caused by electromagnetic radiation on the operation of electronic devices and systems. EMI can originate from both internal and external sources. Internal sources include components within the device itself, such as motors, power supplies, and circuits, while external sources encompass radio frequency interference (RFI) from nearby electronic devices, power lines, and wireless communication signals.

The impact of EMI on electronic devices can range from minor signal degradation to complete system failure. Common symptoms of EMI include flickering screens, audio distortion, data corruption, and erratic behavior. In critical applications such as medical devices, aerospace systems, and industrial machinery, even minor EMI can have severe consequences, making effective shielding solutions imperative.

Shielded Cable: An Overview

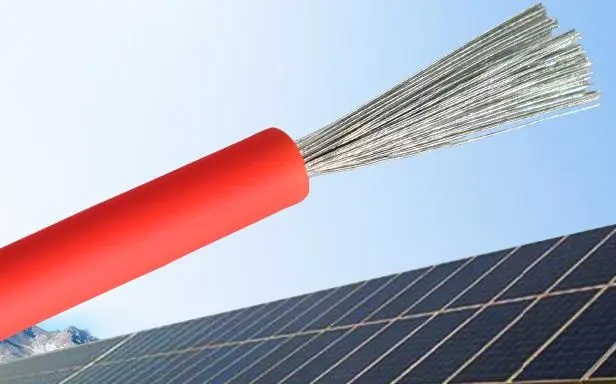

Shielded cable, also known as screened cable, is a type of electrical cable designed to protect signals from EMI by enclosing the conductors within a conductive layer. The primary function of the shield is to mitigate the effects of external electromagnetic fields and prevent interference from affecting the signal transmission. Shielded cable is widely used in various industries, including telecommunications, aerospace, automotive, and healthcare, where reliable signal transmission is essential.

Construction of Shielded Cable

Shielded cable consists of several key components that work together to provide effective EMI protection. The basic construction of shielded cable includes:

1. Conductor: The conductor is the core component of the cable responsible for carrying the electrical signal. It is typically made of copper or aluminum to provide good conductivity and minimize signal loss.

2. Insulation: The insulation layer surrounds the conductor to prevent electrical leakage and ensure signal integrity. Common insulation materials include PVC, polyethylene, and Teflon, each offering different levels of temperature resistance and dielectric strength.

3. Shield: The shield is the critical component of shielded cable that provides EMI protection. The shield can be made of various materials, including copper, aluminum, or a combination of both. It acts as a barrier against external electromagnetic fields and prevents interference from reaching the conductor.

4. Jacket: The jacket is the outer covering of the cable that provides mechanical protection and insulation. It also helps to shield the cable from environmental factors such as moisture, chemicals, and abrasion.

Types of Shielded Cable

There are several types of shielded cable available, each designed for specific applications and EMI requirements. The most common types of shielded cable include:

1. Braided Shield Cable: Braided shield cable consists of a woven mesh of fine wires, typically made of copper, surrounding the conductor. The braided shield provides excellent flexibility and durability, making it suitable for applications where frequent bending and movement are required.

2. Foil Shield Cable: Foil shield cable features a thin layer of metal foil, such as aluminum or copper, wrapped around the conductor. Foil shields offer high EMI protection and are often used in applications where space constraints or weight considerations are critical.

3. Combination Shield Cable: Combination shield cable combines both braided and foil shielding to maximize EMI protection. The combination of braided and foil shields provides superior shielding effectiveness, making it ideal for high-frequency applications and environments with severe EMI sources.

Applications of Shielded Cable

Shielded cable finds widespread applications across various industries where reliable signal transmission and EMI protection are essential. Some common applications of shielded cable include:

1. Telecommunications: In telecommunications networks, shielded cable is used to transmit voice, data, and video signals with minimal interference. Shielded cables help maintain signal quality and integrity in high-traffic areas and reduce the risk of EMI from external sources.

2. Industrial Automation: In industrial automation systems, shielded cables are employed to connect sensors, actuators, and control devices. The shielding of cables ensures reliable communication between components and prevents EMI-induced malfunctions in critical machinery and processes.

3. Medical Equipment: Shielded cable is crucial in medical equipment such as MRI machines, patient monitors, and surgical instruments. EMI protection is vital in healthcare settings to ensure accurate readings, patient safety, and the proper functioning of medical devices.

4. Aerospace and Defense: In aerospace and defense applications, shielded cable is used in aircraft wiring, avionics systems, radar installations, and military communications. The shielding of cables helps safeguard sensitive electronic equipment from EMI generated by external sources or electromagnetic pulses.

Benefits of Shielded Cable

The use of shielded cable offers a myriad of benefits for electronic devices and systems, including:

1. EMI Protection: The primary advantage of shielded cable is its ability to protect signals from electromagnetic interference. By enclosing High ampacity power cable within a conductive shield, shielded cable prevents external electromagnetic fields from affecting signal transmission, ensuring reliable operation of electronic devices.

2. Signal Integrity: Shielded cable helps maintain signal integrity by reducing noise, crosstalk, and signal distortion caused by EMI. This results in improved data transmission, clearer audio/video quality, and enhanced performance of electronic systems.

3. Reliability: Shielded cable enhances the reliability of electronic devices by minimizing the risk of malfunctions and downtime due to EMI. In critical applications where system failure is not an option, the use of shielded cable ensures uninterrupted operation and increased equipment lifespan.

4. Compliance: Shielded cable is often required to meet industry standards and regulations related to EMI protection. By using shielded cable in compliance with relevant standards, manufacturers and users can ensure the safety, performance, and reliability of their electronic products.

5. Versatility: Shielded cable is available in various configurations, sizes, and shielding types to accommodate different applications and EMI requirements. Whether in telecommunications, automotive, or aerospace, shielded cable offers a versatile solution for diverse industries and environments.

Conclusion

In conclusion, shielded cable plays a crucial role in mitigating electromagnetic interference and ensuring reliable signal transmission in electronic devices and systems. By enclosing the conductors within a conductive shield, shielded cable protects signals from external electromagnetic fields, reduces EMI-induced malfunctions, and enhances the performance and longevity of electronic equipment. With its diverse applications, construction options, and benefits, shielded cable remains an essential solution for addressing the challenges posed by electromagnetic interference in today's interconnected world.

References:

1. Ott, H. W. (2009). Electromagnetic Compatibility Engineering. John Wiley & Sons.

2. Morrison, R. L. (2011). Grounding and Shielding: Circuits and Interference. John Wiley & Sons.

3. Tzounas, D., & Morris, K. (2009). Shielding for EMC: A Handbook for Design and Installation. Newnes.

4. Williams, T. (2000). EMC for Product Designers. Newnes.

5. Paul, C. R. (1992). Introduction to Electromagnetic Compatibility. John Wiley & Sons.